Weightlifting Bars & Plates * | Rogue Fitness Rogue Hybrid Power Bar

$395.00 $89.99

Weightlifting Bars & Plates * | Rogue Fitness Rogue Hybrid Power Bar

Rogue Hybrid Power Bar

The Rogue Hybrid Power Bar Represents Another Step Forward In Precision Machining, Combining Tighter Tolerances With Recent Innovations From Our Popular Aggro Power Bar To Create A Superior Lifting Experience.

Starting With The Traditional “Core Four” Attributes Of A Standard Power Bar Aggressive Knurl, Center Knurl, Reduced Whip, And Controlled Spin We Went To Work Exploring Ways To Better Optimize Each Of These Features To The Demands Of Today’S Serious Powerlifter. This Included Absorbing A Decade’S Worth Of Feedback From Customers, Athletes, And Gym Owners, And Calibrating It With Our Own Wealth Of Experience Outfitting Gyms And Competitions At The Highest Levels Of The Iron Game. Additionally We Have Commissioned Extensive Research Into Ways To Improve Every Aspect Of Barbell Design And Manufacturing.

With This In Mind, Some Aspects Of The Hybrid Power Bar Including The 2Xaggro Knurl Tested Too Well To Make Any Changes. For Other Areas, We Refined Our Processes To Establish A New Blueprint For A Truly Optimized Powerlifting Barbell That’S Also Uniquely Versatile Compared To Its Competitors. Some Of These Specific Features Are Detailed Below:

Built With Uncoated Stainless Steel And Our Ultra-Aggressive 2Xaggro Knurl, The Grip Is Perfect For Powerlifting; Feeling Exactly The Same As When It Comes Out Of The Lathe And Exactly As We Intended. Uncoated Bars Result In A Grip That Is Very Firm And Less Reliant On Chalk, But Not Overly Sharp Or Uncomfortable On The Hands/Back/Neck. To Make The Sleeves As Maintenance-Free As The Shafts, We Chose Our Proprietary Matte Black Finish, Which Converts The Surface Of The Steel And Will Stay Black Much Longer Than Other Black Finishes.

The Most Obvious Difference Between The Rogue Hybrid Power Bar And The Remainder Of Our Power Bar Line Is Our Choice Of A 28.5 Mm Shaft Instead Of A 29 Mm Shaft. This Accomplishes Two Things. First, The Knurl Feels More Prominent Than It Would On A Thicker Shaft. Second, The Narrower Design Benefits Athletes That Incorporate Power Cleans Or Other Olympic Lifts Into Their Powerlifting Program, As It Makes The Hook Grip Easier To Achieve. It Is Also Helpful For Deadlifts, Where A Slightly Smaller Shaft Leads To A More Reliable Grip.

We Added New Precision Machined Bronze Bushings That Fit Tighter Around The Shaft, Leading To Less Radial Endfloat. We Have Also Tightened The Tolerances Around Our Sleeve Attachment, Leading To Less Axial Endfloat. This Results In A Reliable Controlled Spin That Is Not So Free-Spinning As To Cause Instability When Benching Or Squatting And Will Not Keep Spinning At The Top Of The Clean.

To Develop Our Sleeve Surface Profile, We Provided The Usa Weightlifting Team With A Number Of Different Sleeve Finishes Ranging From Completely Smooth To Different Sizes And Depths Of Grooves. Our Current Sleeve Finish With 41 Grooves Per Inch Was The One That Was Overwhelmingly Chosen By The Athletes Competing In The World Championships As Well As Pyrros Dimas. By Using Advanced Optical Profilometry To Gauge The Sleeve Finish, We Are Able To Ensure The Profile Of The Sleeve Is Always Exactly As Designed.

We Chose A Very Specific Stainless Steel That We Discovered When Developing The Elephant Bar For The Deadlift Competition At The Arnold Strongman Classic. This Steel Has A Tensile Strength Of 200,000 Pounds Per Square Inch And A Yield Strength Of 170,000 Pounds Per Square Inch.

Tensile Strength Is The Amount Of Stress That It Takes To Cause The Steel To Fail. Yield Strength Is The Resistance Of The Metal To Becoming Permanently Deformed In Response To Stress. In Practice, Yield Strength Is What Keeps The Bar From Becoming Bent During Use.

Steel Products Should Be Built From Materials With Adequate Tensile And Yield Strength, But These Properties Should Not Be Increased Above This Level, Because It Will Decrease Toughness. Despite This, Many Companies Elevate Their Tensile Strength In An Arms Race To Be Able To Advertise Higher Numbers, But Instead Decrease The Longevity Of Their Barbells.

In Our Testing, The Maximum Stress That A Barbell Shaft Experienced Was 144,000 Pounds Per Square Inch. Therefore The Yield Strength Of 170,000 Pounds Per Square Inch Is Well Above What A Bar Would Experience In Normal Use, While Not Requiring Our Tensile Strength To Be Elevated Above What Is Required. The Amount Of Whip That A Bar Has Is Predominantly Determined By The Diameter Of The Shaft, But Can Be Influenced By The Tensile Strength Of The Steel. For This Reason, We Chose A Tensile Strength That While Being In The Optimum Range, Between 190,000 Psi And 215,000 Psi, Is Still Higher Than Most Bars On The Market.

In Addition To The Specifications Of Our Stainless Steel, Which Are Optimized For Barbell Performance, Both Short Or Long Term, We Have Found That Our Stainless Steel Has A Greater Resistance To Becoming Bent Than Other Steels With The Same Tensile And Yield Strength.

Our Stainless Steel Is Also Particularly Well Suited To Having Its Fatigue Life Increased By Our Rogue Work Hardening (Rwh) Process. The Areas Of The Shaft That Receive The Greatest Stress Are Treated With Our Patented Rwh. Rogue Work Hardening Of Our Stainless Steel Leads To An Even Longer Fatigue Life Than Our Other Barbell Steels, Which Are Already Many Times More Durable Than What Is Available From Other Manufacturers. With A Tested Score Of F-10R, The Rogue Hybrid Power Bar Has The Highest F-Scale Durability Rating Of Any Rogue Barbell With Standard-Length Sleeves.

By Designing The Rogue Hybrid Power Bar With Serious Lifters In Mind, Taking Into Account All We Have Learned About Barbell Manufacturing And Making No Compromises With Respect To Materials Or Manufacturing Practices, We Have Created A Barbell That Will Become The Go-To Bar For Athletes At All Levels.

Be the first to review “Weightlifting Bars & Plates * | Rogue Fitness Rogue Hybrid Power Bar” Cancel reply

Related products

Weightlifting Bars & Plates

Weightlifting Bars & Plates * | Rogue Fitness Rogue Echo Bumper Plates V2

Weightlifting Bars & Plates

Weightlifting Bars & Plates * | Rogue Fitness Rogue Heavy Rail Monster Lite

Weightlifting Bars & Plates

Weightlifting Bars & Plates * | Rogue Fitness Rogue Deep Dish Plates

Weightlifting Bars & Plates

Weightlifting Bars & Plates * | Rogue Fitness Rogue Color Lb Training 2.0 Plates

Weightlifting Bars & Plates

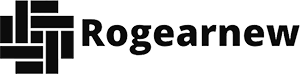

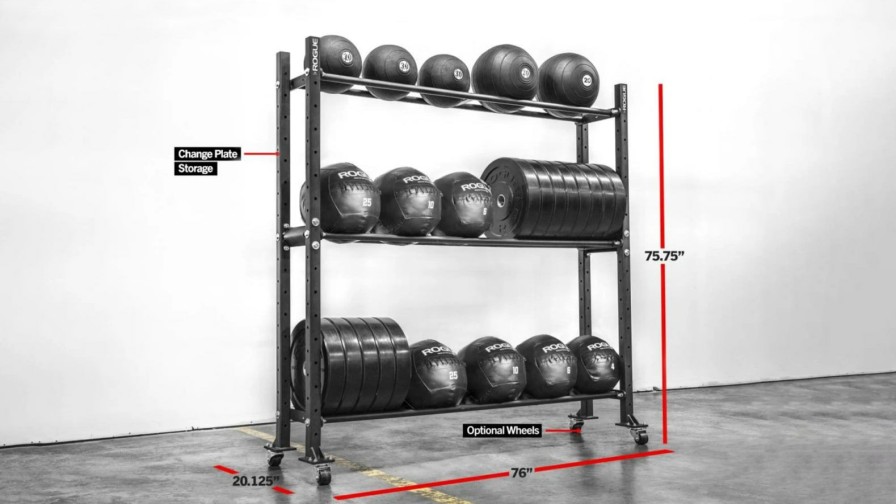

Weightlifting Bars & Plates * | Rogue Fitness 3-Tier Mass Storage System 70

Weightlifting Bars & Plates

Weightlifting Bars & Plates * | Rogue Fitness Rogue Euro 28Mm Olympic Weightlifting Bar

Weightlifting Bars & Plates

Weightlifting Bars & Plates * | Rogue Fitness Rogue Deep Dish Plate Arnold Edition

Weightlifting Bars & Plates

Weightlifting Bars & Plates * | Rogue Fitness Rogue Hg 2.0 Collars

Reviews

There are no reviews yet.